Stainless Steel is a commonly used construction material for numerous pool, pond and fountain products. While stainless steel is a great metal for these products, customers often have poor experiences with these products due to lack of knowledge of the necessary grades and processes necessary to create a metal product that will have the least amount of maintenance over time.

Many times, manufacturers use lower grades of stainless steel to reduce their costs, but the cost of replacement will far exceed the cost of getting the right grade product up front.

Types of Stainless Steel Products found in Pools, Ponds & Fountains

- Pool Scuppers

- Fountain Spouts

- Pool Handrails

- Pool Ladders

- Plumbing Connectors & Piping

- Pool Fountain Tile

- Fountain Basins

Common Grades of Stainless Steel for Pool, Pond & Fountains

Common grades of stainless steel for pool, pond and fountain products are 304, 316 and Aerospace. Below you'll find a chart of the value of each grade for these applications.

| Factor | 304 Grade SS | 316 Grade SS | Aerospace SS |

|---|---|---|---|

| Composition | Chromium: 18-20% Nickel: 8-12% Manganese: Up to 2% Silicon: Up to 0.75% Nitrogen: Up to 0.10% Carbon: Up to 0.08% Phosphorus: Up to 0.045% Sulfur: Up to 0.03% Iron: Makes up the remainder | Chromium: 16–18% Nickel: 10–14% Molybdenum: 2–3% Manganese: Up to 2% Silicon: Up to 0.75% Nitrogen: Up to 0.10% Carbon: Up to 0.08% Phosphorus: Up to 0.045% Sulfur: Up to 0.03% Iron: Makes up the remainder | Chromium: 21-23% Nickel: 4.5-6.5% Molybdenum: 2.5–3.5% Manganese: Up to 2% Silicon: Up to 1% Nitrogen: Up to 0.20% Carbon: Up to 0.03% Phosphorus: Up to 0.03% Sulfur: Up to 0.02% Iron: Makes up the remainder |

| Attributes | Good Corrosion Resistance, Heat Tolerant, High Strength | High Corrosion resistance, High Strength | Best in Class Corrosion Resistance, High Strength |

| Standard Usage | Food Processing, Sinks, Utensils, Furniture, Building Construction Parts | Boat Parts, Industrial Equipment, Medical Equipment, Architectural, Water Piping | Space Exploration Vehicles, Hazardous Chemical Tanks and Pipes, Nuclear Power Cooling Systems |

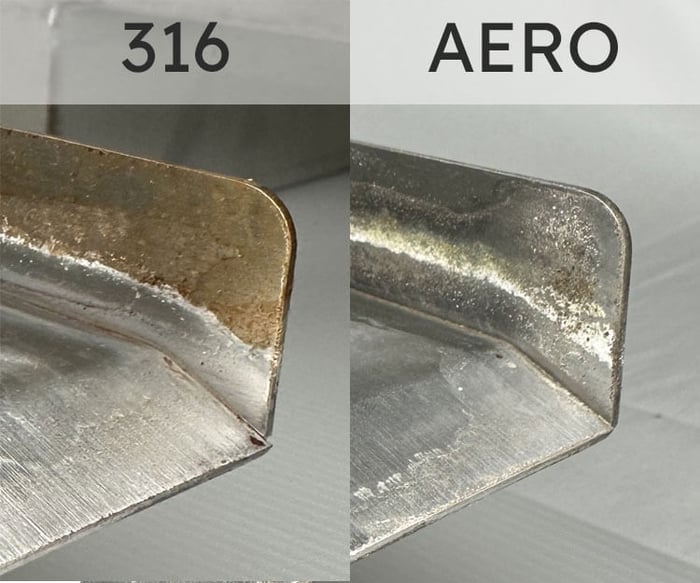

| Pool, Pond & Fountain Friendly? | Only In Freshwater with no chemicals added | Yes for all, but will surface corrode with time. | Yes for all, minimal to no surface corrosion. |

| Required Maintenance Intervals | Regularly in a chemical aqueous environment. | 3-6 Months in usual applications. | 1-5 Years in usual applications. |

| Corrosion Resistance | Low in Chlorinated environments. | Good in Chlorinated environments. | Excellent in Chlorinated environments. |

| Cost | Low | High | Very High |

| Strength | 215 HB | 149 HB | 293 HB |

| Ease of Fabrication | Easy to Machine & Fabricate. | Moderate to Machine & Fabricate. | Difficult to Machine & Fabricate. |

Acceptable Grades of Stainless Steel for Ponds with Fish

For ponds where fish will live, it's advised to use the best grade of stainless steel you can purchase. Corrosion is the major issue with living environments and can create a toxic environment for living things.

316 grade is a "high-end" stainless steel that is suitable for most pond products, while 304 is very common. Corrosion can be prevented with post treatments or applied finishes to keep the metal from being exposed to the elements.

What can compromise grades of Stainless Steel?

Alloy Quality

The "alloy" of a metal is the mixture of materials it is composed of. Stainless steel grades are a different blend of materials to compose them for a specific purpose. If the blend of materials in a batch of molten stainless steel is not well mixed, the material can have variations in the alloy throughout the sheet or solid, compromising the expected performance, potentially leading to corrosion and lack of strength.

Introduction of other Ferrous / Different Metals

When a part or product is being worked, it is important that other metals, specifically those with lower standards for corrosion are not introduced. This can come from many sources, but predominately fabrication work. Grinding dust, using the same abrasives on multiple materials, finishing with a wire brush, welding with the wrong wire and sandblasting are a few examples of processes that can introduce undesired particles/dust from metals that will corrode, accelerating the corrosion process.

Disturbance of the Protective Oxide layer

Stainless Steel maintains its corrosion resistance by forming an passive oxide layer. If this oxide layer is damaged, the stainless steel can corrode without this vital layer of production. If the material is scratched, it must be post processed to bring back the oxide layer. If time is not an issue, the oxide layer will form naturally.

Lack of maintenance

Clean Stainless Steel is less likely to corrode. Buildup of hard water deposits on stainless steel, for example, provides an environment for accelerated corrosion. Cleaning and removing deposits is an essential part of maintenance of Stainless Steel products, especially in corrosive environments like pools and fountains.

Post Treatments

Pickling

Pickling is a chemical process using a strong acid solution that is used to remove surface impurities and weld oxide/scale. Pickling solution are usually composed of Nitric Acid, Hydrofluoric acid OR Sulfuric Acid and water.

Pickling solutions with strong acid concentration may alter the finish of the Stainless Steel it's applied to, leaving a dull/matte/etched finish that is not passive or corrosion resistant.

Common forms of pickling solutions are liquid for dipping, and gels/pastes for brushing on.

Passivation

Passivation is a chemical process that restores the natural corrosion resistance of Stainless Steels after cutting, sanding, and welding of materials. Made from Nitric or Citric Acid, they are much lower in acidic concentration than pickling solutions. The passivation process goal is to enhance the chromium level on the surfaces of the product.

The surface finish of the product will not change with passivation. Passivation removes free irons and oxidizes the surface in a short time without any change to the appearance.

Passivation is normally a liquid form for dipping in a heated tank, but can be found in gel/pastes, as well.

Electropolishing

Electropolishing stainless steel is an electrochemical process that removes a thin surface layer and generates a smoother surface finish. The electrolyte used for electropolishing is commonly a mix of phosphoric and sulfuric acids with a DC electrical current applied to the anode (product) and a cathode that will receive the removed material. Electropolishing can be used as a substitute for mechanical grinding and polishing.

Electropolishing will smooth the surface finish of the product, creating a shinier appearance to the product. Electropolishing only increases the corrosion resistance of stainless steels by creating a less rough finish, with a oxide film that is far less passive than passivated products.

Electropolishing is a process that is performed by dipping the product in a tank of liquid.

Applied Finishes

Powdercoat

Powdercoating is a common applied finish due to its ease of application and long-lasting properties. Stainless steel is an excellent substrate for powdercoating as it adheres very well when clean and lightly abraded.

The process of powdercoating starts with electrostatically applying a powder to a product and then heating the powdered product in an oven until the powder melts to be one solid surface finish.

Powdercoating is a popular finish to protect stainless steel from environmental elements and apply color.

Lacquers & Paints

Lacquers and Paints are commonly applied to stainless steel as the most cost-effective method for adding color and environmental protection to a product. Stainless steel is ideal for painting when cleaned well and lightly abraded.

The process of painting includes application of the paint or lacquer with a brush or spray gun.

The longevity of a painted or lacquers stainless steel product depends on the conditions it's exposed to, quality/composition of finish to be applied and the preparation of the product prior to coating. Paints and lacquers are not recommended for pool and fountain products.

Plating

Stainless steel can be plated with other metals to modify the finish appearance. Zinc, Gold, Copper, Nickel, and Chrome are common materials that can be plated to stainless steel. Stainless Steel is an excellent substrate for plating.

Plating is performed on stainless steel by electrolytic deposition onto the product. This process is essentially the reverse of electropolishing.

A plated product has a thin layer of the plated metal, which is ideal for cost-effective production of products that do not see harsh environments. Therefore, it's not recommended for water feature products in pools and fountains.

Maintenance of Stainless Steel in Pools, Ponds and Fountain Water Features

Products of all grades of Stainless Steel will need maintenance to ensure they are looking their best and corrosion/rust free.

304 will require the most maintenance, 316 will require a lesser amount of maintenance and Aerospace grade will require the least amount of maintenance.

For more information on Stainless Steel Maintenance, see our in-depth article on the subject linked below.

Stainless Steel Pool & Fountain Scupper Maintenance

Quality of Materials and Processes at Majestic Water Spouts

At Majestic Water Spouts, we only offer products made from 316 and Aerospace grades of Stainless Steel. Our materials are tested upon arrival at our facility with XRF X-Ray devices for quality of material, passivated and thoroughly cleaned prior to arriving at your door. The Majestic quality is backed by our Limited Lifetime Craftsmanship Guarantee that you will not find elsewhere!

While you may find less expensive alternatives and copies of our products, we believe that you'll find our stainless steel pool and fountain products to be of higher quality. When you're building a fountain or pool, the last thing you want to be doing in a year is replacing scuppers, costing $1000's when you could have prevented that to start.

Where to Purchase Quality Stainless Steel Pool, Pond and Fountain Products?

For a large selection of water feature products made from quality materials see Majestic Water Spouts pond, pool and fountain scupper, spouts and spillways!

Shop Online for Pond, Pool and Fountain Scupper, Spouts and Spillways